Retainers keep the balls evenly spaced around the raceway preventing ball to ball contact and thus allowing higher speeds. They also help to retain grease around the balls and raceways. For greater accuracy and to prevent any additional friction, it is important that the retainer is not allowed too much radial movement. To achieve this, the retainer is guided by either the balls or one of the rings. See the sections below for information on how each cage type is guided.

Standard bearing retainers are made from cold rolled carbon steel however, in cases of corrosive environment, misalignment, or high speed operation, stainless steel, or phenolic resins will be used upon request.

1.ONE-PIECE STEEL CROWN RETAINER:

This standard retainer is manufactured from carbon steel for chrome bearings and AISI304 or AISI430 grade stainless steel for stainless bearings. These were often made from brass which also offered a high temperature capability but this is much less common due to higher cost of brass and advances in steel technology.

The stainless steel pressed cage is Inner ring guided,It shows excellent performance in low torque, low speed application.

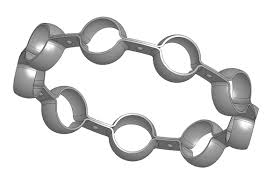

2.TWO-PIECE STEEL RIBBON RETAINER:

Consists of two mating steel pressings, The cover side and the finger side. Usually guided by the rolling elements and designed to reduce frictional torque, The closed pocket design of the ribbon retainer is the most common type.

The material used is 1Cr18Ni9 stainless steel, For low torque applications a loose clinched ribbon retainer may be available.Ribbon cage is mainly ball guided.

3.ONE-PIECE NYLON CROWN RETAINER:

Nylon crown retainers have the highest speed ratings of any standard retainer type, But have limited availability, Moulded Nylon cage reduces the fluctuation in running torque, Suitable for high speeds guided by the rolling elements.

4. NYLON CROWN retainer is ball guided.

For specific applications,Please contact MANV INTERNATIONAL Concerning availability and compatibility of different retainers type.